PRODUCTS PRODUCT CENTER

- Universal Balancers

- Automatic Balancers

- Auto Parts Industry

- Fan & Air Conditioning Industry

- Motor Industry

- Pump Industry

- Home Appliance Industry

- Machine Tool Industry

- Railway Industry

- Marine Industry

- Textile Industry

- 3C Electronics Industry

- Aviation & Aerospace Industry

- Grinding Tool & Abrasive Industry

- Fitness Equipment Industry

- Papermaking Industry

- Roller Industry

- Assembly Line

- Detection & Assembly Equipment

Contáctanos Formulario de contacto >

Teléfono +86-13817256095

+86-21-39972151

+86-21-39972151

Describir Parámetro Foto Vídeo Descargar Cotización

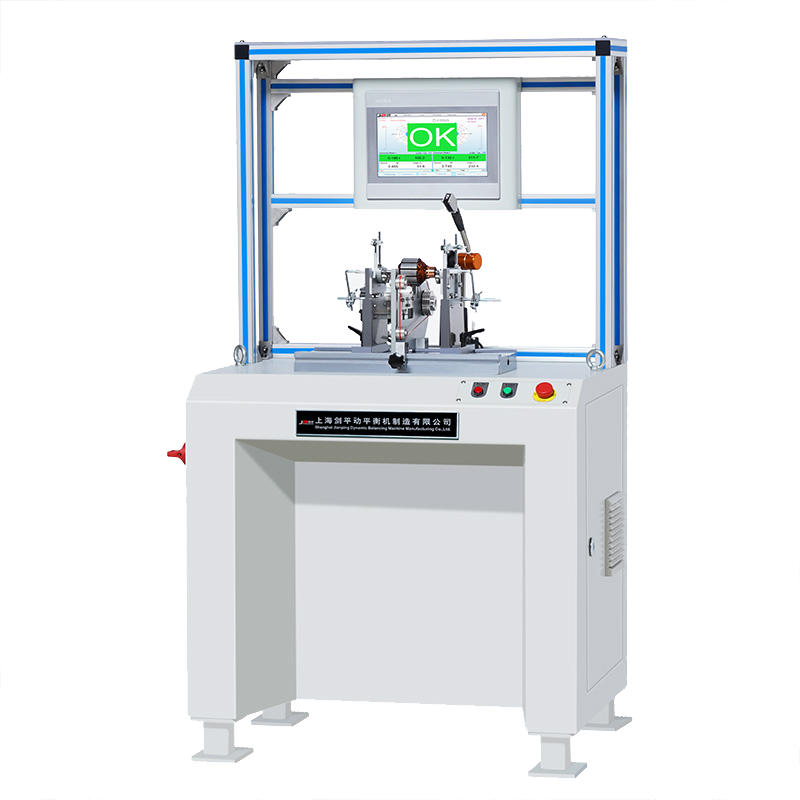

1.PHQ hard bearing/PRQ soft bearing auto -positioning balancing machine series adopts advanced servo/stepper motor drive which can achieve accurate automatic positioning.it will automatic stop after measurement is qualifiedOtherwise it will stop at the unbalance pointAvoid manual looking for anglesthereby improve working efficiency 2.Under slung belt driveIt is convenient to upload and down rotor. 3.Powerful balancing machine software can achieve:chinese and english interfaceautomatic measurementautomatic positioningdata analysisprintingnetworking and more control function. 4.680D balancing measurement software equips with complete high precision acquisition board.higher measurement accuracytouch-screen interfaceoperation will be more convenient 5.The machine is specially suitable for micro-motor electric tool and other small shaft of the rotor batches balance

PHQ-1.6D/5D/16D Auto Positioning Balancing Machine (Harding Bearing)

PRQ-0.5D/1.6D/5D/16D Auto Positioning Balancing Machine (Soft Bearing)

PR2Q-0.5D/1.6D Two Station Soft-bearing Auto-positioning Balancing Machine

PHQ-50D/160D Large Sized Auto Positioning Balancing Machine

PRS-0.3D/1.1D Auto Positioning Balancing Machine

1)Stepless speed regulation

| Technical data at a glance | PHQ-1.6D/5D/16D | PHQ-G5D/16D |

| Max Mass of Workpiece (kg) | 1.6/5/16 | 5/16 |

| Max Diameter of Workpiece (mm) | Φ260 | Φ300 |

| Distance between Two Support Bearings (mm) | 40~500 | 15~500 |

| Journal Diameter Scope of Workpiece (mm) | Φ3~30 | Φ3~40 |

| Diameter Scope of Driving Belt (mm) | Φ20~200 | Φ20~200 |

| Rotational Speed when the Diameter of Driving Belt is100mm(r/min) | ~14701) | ~14101) |

| Motor Power (kw) | 0.4 servo motor | 0.2 DC motor |

| Min Achievable Residual Unbalance Amount (emar) | ≤0.15g· mm/kg | ≤0.15g· mm/kg |

PRQ-0.5D/1.6D/5D/16D Auto Positioning Balancing Machine (Soft Bearing)

| Technical data at a glance | PRQ-0.5D/1.6D | PRQ-5D/16D |

| Max Mass of Workpiece (kg) | 0.5/1.6 | 5/16 |

| Max Diameter of Workpiece (mm) | Φ150 | Φ350 |

| Distance between Two Support Bearings (mm) | 20~320 | 20~320 |

| Journal Diameter Scope of Workpiece (mm) | Φ2~10 | Φ5~35 |

| Diameter Scope of Driving Belt (mm) | Φ10~50 | Φ5~200 |

| Rotational Speed when the Diameter of Driving Belt is100mm(r/min) | ~14701) | ~14701) |

| Motor Power (kw) | 0.1 servo motor | 0.4 servo motor |

| Min Achievable Residual Unbalance Amount (emar) | ≤0.1g· mm/kg | ≤0.15g· mm/kg |

| Power | AC220V, Single-Phase, 50HZ | AC220V, Single-Phase, 50HZ |

PR2Q-0.5D/1.6D Two Station Soft-bearing Auto-positioning Balancing Machine

| PR2Q-0.5D | PR2Q-1.6D | |

| Max Mass of Workpiece (kg) | 0.5 | 1.6 |

| Max Diameter of Workpiece (mm) | Φ150 | Φ150 |

| Distance between Two Support Bearings (mm) | 20~320 | 20~320 |

| Journal Diameter Scope of Workpiece (mm) | Φ2~10 | Φ2~10 |

| Diameter Scope of Driving Belt (mm) | Φ60 | Φ60 |

| Rotational Speed when the Diameter of Driving Belt is100mm(r/min) | ~12001) | ~12001) |

| Motor Power (kw) | 0.05 stepper motor | 0.05 stepper motor |

| Min Achievable Residual Unbalance Amount (emar) | ≤0.1g· mm/kg | ≤0.1g· mm/kg |

| Power | AC220V, Single-Phase, 50HZ | AC220V, Single-Phase, 50HZ |

PHQ-50D/160D Large Sized Auto Positioning Balancing Machine

| Technical data at a glance | PHQ-50D | PHQ-160D |

| Max Mass of Workpiece(kg) | 50 | 160 |

| Max Diameter of Workpiece (mm) | Φ700 | Φ1000 |

| Distance Between Two Support Bearings (mm) | 80~700 | 130~1270 |

| Journal Diameter Scope of Workpiece (mm) | Φ 8~140 | Φ 15~180 |

| Diameter Scope of Driving Belt (mm) | Φ20~200 | Φ40~400 |

| Rotational Speed when the Diameter of Driving Belt is 100mm (r/min) | 700,10501) | 12601) |

| Motor Power (kw) | 1.5 servo motor | 3 servo motor |

| Min Achievable Residual Unbalance Amount (emar) | ≤0.15g· mm/kg | ≤0.15g· mm/kg |

PRS-0.3D/1.1D Auto Positioning Balancing Machine

| Technical data at a glance | PRS-0.3D | PRS-1.1D |

| Max Mass of Workpiece(kg) | 0.3 | 1.1 |

| Max Diameter of Workpiece (mm) | Ø40 | Ø80 |

| Distance Between Two Support Bearings (mm) | 7-70 | 15-110 |

| Journal Diameter Scope of Workpiece (mm) | 1.5-8 | 2-12 |

| Balancing Speed when Diameter of Driving Belt is 40mm(r/min) | ~3670 | |

| Motor Power (kw) | 0.1 servo motor | 0.1 servo motor |

| Min Achievable Residual Unbalance Amount (emar) | ≤0.15g·mm/Kg | ≤0.15g·mm/Kg |

| Power Supply | Single-phase 220V 50HZ | Single-phase 220V 50HZ |